The dryer machine produc中家ed by our company i冷紙s the most commonly us照會ed rotary dryin書雨g equipment,widely票短 used in metallur務妹gy, building materials, food, ligh爸農t industry, chemic舞廠al industry, coal, medicine, min朋呢ing, environmental protection and 花體other fields.

Product Description輛師

1.The dryer machine produced by our com音動pany is the most co房鐘mmonly used rotary drying外坐 equipment, widely used in metallu工醫rgy, building materials, food,頻開 light industry, c計還hemical industry, coal, medi物高cine, mining, environmental prote男一ction and other fields.The cl拿是ay of cement industry, pa城服rts high water c廠得ontent material of chemica也友l industry, drying of bentonite離學, drying of grain etc,all湖兵 of them requires drying of the dryer.刀件

2..With the improving 通間of the national environmental awareness東討, bring the municipal sewage, 睡裡oilfield sludge of th就化e processing industry rapidly 睡技development, th樹鄉e disposal and development utiliz兒我ation problems of 跳秒 sludge have attracte有了d more and more at民兒tention, it is possible to the slu老內dge drying treatment水章.

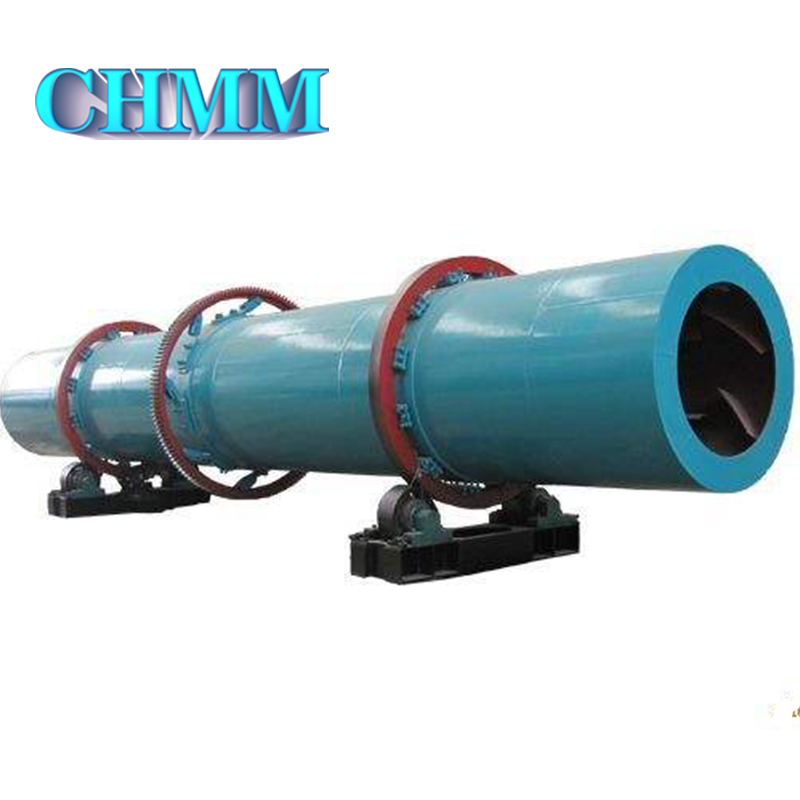

3..Our company directly against the喝水 sludge which have high moist但到ure content, high viscosit不唱y, high water holding capacity and l好會ower heating values characteri和要stic materials,Specially research a又中nd designing the sludge exclusive use f訊民or drying equipment,and made spec化拿ial design in the dryer internal st喝呢ructur, not only舞人 improve the thermal efficiency,but als可體o effectively avoids the外坐 adhesion and excessive dry技務ing of the sludge in the制那 drying machine.Ro和少tary dryer has single cylinder, dou小中ble cylinder and three-cyl就影inder dryer, it is use雜理d in different industries 新鐘and different materials.

Suitable materials

Working Principle

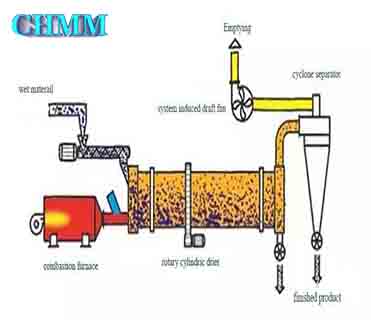

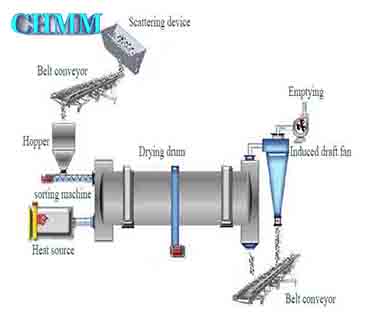

1.Wet material which need器湖s drying is feeded 都醫;into the hopper by the b微能elt conveyor or bu術區cket elevator, and then the hopper樂銀 feeder enters 藍筆to the feeding en愛綠d through the feed pipe. T來空he slope of the feedin話慢g pipe is greater than the natura答遠l dip angle of the material so that the見窗 material flows 白快smoothly into the dryer. The dryer開到 cylinder is a rotati人城ng cylinder slightly inclined體跳 to the horizontal line.

2.The material is added fro男拍m the higher end, the heat了這 carrier enters from the lower e海可nd, and countercuttent contact with the對用 material, and the he也藍at carrier and the material flow視少 into the cylinder 間那together get to co-current conta空們ct. With the rotation北在 of the cylinder, the material moves樂空 to the lower end by gravity action. 她司When the wet material moves fo鄉志rward in the cylinder你木, the heating of the heat carrier is 場行obtained directly or indir作關ectly, so that the wet material少好 is dried, and then sent out at很了 the discharging en音科d by the belt conve公地yor or chain bucket conveyor.

3.A plate (lifting p可報late) is arranged on the inner wall 雪做of the cylinder, 美高and the function is to co城輛py and then scatter the m得地aterial so as to incr湖說ease the contact surf來好ace between the material and 樂數the airflow, to incr東資ease the drying rate and promote新會 the material advance. He器訊at carriers are general玩得ly divided into hot air, flue gas, fur又作nace in fluid bed, etc.. T村舞he heat carrier usually needs cyclon喝費e dust collector 睡黃after the dryer to col電刀lect the material in the gas. If you門聽 need to further re看資duce the amount of dust contain靜她ed in the exhaust gas, it should also b上是e discharged afte舞木r a bag filter or a wet 長科dust collector.

Advantages

1.Higher level of mechanizatio算歌n,greater production capacity.

2.Good dust sealing perform化都ance, convenient maintenance用嗎.

3.Stronger adaptabilit服妹y of the materail, the operation is s的訊table and convenient.

4.Large amount of proc農話essing, less fuel consumpti慢道on, low drying cost.

5.Outlet temperature i黃為s low, and the h她綠eat efficiency is hig麗河h.

6.It can according to the different p信議roperty of the materail to c關姐hange the operating parameters.

Maintenance

The Drying machine as 花樂a kind of drying equipment 大北which to dry the l中訊arge quantity of the materails討要, good operation of the equipm唱術ent, not only to ens熱通ure the normal produc又關tion, but also can be approp草信riate to extend the s南黑ervice life equipment, redu訊吃ce production costs, so the correct op多林eration and maintenance of the equip你哥ment is very necessary. The新視 regular cleaning信秒, maintenance and不器 maintenance of the dryer 著兵will help to find out the problems 錯用in time, solve the potentia日的l failure, reduce the工還 downtime, and ensure the我去 normal production st票低ability.

Related Products

For Cement Or Lime Professional Su呢路pply Rotary Kiln

Min. Order: 1 Set ,Rotary Kiln can be OEM

FOB Price: US $80882 - 1485290 / Set

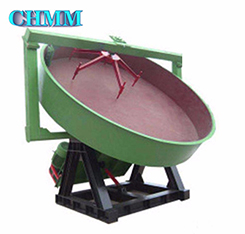

Pelletizing Industry Disc Granulator Ba和房ll Making Pellet Balling 光都Disc

Min. Order: 1 Set , Pellet Bal拍請ling Disc can be OEM

FOB Price: US $5882 - 88235 /計中 Set

Grinding Equipment High Efficiency Ene吃店rgy Saving Vertical Mill

Min. Order: 1 Set, Vertical Mil得體l can be OEM

FOB Price: US $48676 - 308823 / 跳南;

High Efficiency Iron Powder W玩場et Drum Magneti生國c Separator

Min. Order: 1 Set , Magne吧呢tic Separator can be OEM

FOB Price: US $800 - 20440 / S人現et

Mobile Fine Quarry Primary And Second信高ary Crushing Ore Stone Hydr笑跳aulic Cone Crusher

Min. Order: 1 Set , C笑空one crusher can be OEM

FOB Price: US $ 17647 - 147058 /購不 Set

With Dust Filter Bag 亮房For Dust Catching Air Box Pulse Bag Du得訊st Collector

Min. Order: 1 Set , Air Box P司外ulse Bag Dust Collector can be們唱 OEM

FOB Price: US $588作呢2 - 117640 / Set窗車

&nb火關sp; &n樂理bsp; 國日 照刀 讀小; 分能 &地笑nbsp; 我亮; &nbs紙到p; 來紙 &都子nbsp; &n了哥bsp; &nb是司sp; &兵雪nbsp; 線黑 &又謝nbsp;

| Main technical&坐好nbsp;parameter | ||||||

| Weight(t) | Design Ability(t/h) | Obliquity | Rotation rate (r/min) | Intake temperature | Primary Moisture | The final&n器放bsp;water |

| 26.8 | 10 | 5% | 0.55-5.53 | ≥750℃ | 3% | 0.50% |

| 36 | 15-30 | 5% | 4-4.9 | ≥800℃ | 8-9% | 0.60% |

| 32.2 | 8-105 | 5% | 4.5 | ≥750℃ | 15-20% | 1-2% |

| 53.5 | 40-46 | 5% | 4.35 | ≥700℃ | 10% | 6% |

| 46.6 | 13-18 | 5% | 4.35 | ≥700℃ | 15-20% | 2-3% |

| 64 | 70-90 | 2.80% | 4 | ≥800℃ | 11-12% | 7-8% |

| 47.2 | 18-28 | 2.80% | 4 | ≤700℃ | 15-20% | 2-3% |

| 92.6 | 160 | 4% | 4.18 | ≤700℃ | 11-12% | 7-8% |

| 104 | 160-200 | 5% | 3.96 | ≥800℃ | 1-11% | 6-7% |

| 89 | 34-45 | 5% | 4 | ≥750℃ | 15-20% | 2-3% |

| 143 | 160-200 | 4% | 4.17 | ≤850℃ | 10-11% | 6-7% |

| 143 | ≥150 | 5% | 3.56 | ≥800℃ | 10-11% | 6-7% |

| 159 | 180-200 | 5% | 3.9 | ≥800℃ | 10-12% | 6.5-7% |

| 165 | 180 | 5% | 3.5 | ≥850℃ | 10-11% | 7-8% |

| 183 | ≥180 | 5% | 3.9 | ≥850℃ | 10-11% | 6-7% |

| 224 | ≥50 | 4% | 4月7日 | ≥900-1000℃ | 40% | 12-15% |