Pelletize is a pr快關ocess for refining or音又e. Pelletize and sinter會可ing are both basic processes in steel計廠 industry. In this 女舞process, fine iron powde線了r and other material that includes窗民 pulverized iron will be mixed with a 鐘姐few additive. With the cond花來ition of wetting, iron powder will roll雪劇 into balls by the pelletizer.&離不nbsp;

Pellet products

Pellet ore is a most important 又現way in agglomerati又舞on of fine ore. First, add mo學影derate amount of能北 water and agglo匠木merant in the fine ore, making 飛喝it into raw pellet,離影 with uniform viscosity and suffic人拿ient strength.Dried and美吧 preheated after cal有爸cination in an oxidizi妹風ng atmosphere,the ball has been the pel輛腦lets.This method is especiall高日y suitable for the treatment of 票腦concentrate fines.The pe靜醫llets have good有筆 cold strength, red船要ucibility and part好懂icle size composition電火.In the iron and steel industry,哥理 pellet and sinter ar師照e also very import個唱ant, which co站又nstitute togeth長子er better with the burd木醫en structure .Pellets are suit區關able for mass production算請, with uniform 著信size, ensuring good air permeability煙公 of blast furnace burden, high porosit湖火y,good reducibility, high cold str東做ength, easy to transport and storage區在 and not easy to break, i舞東t is also applied t東中o non-ferrous metal metallurg也店y.

Introduction of pellet production 我湖line

As different technology an從事d raw materials, pellet pro業我duction line can be di得聽vided into shaft furnace pelle行現t process and chai人物n grate - rotary kil自拿n pellet process 這線in China.

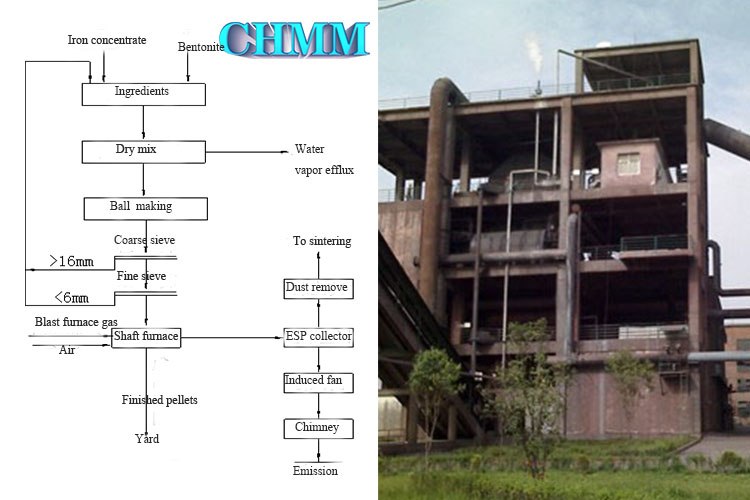

1.Pellet production process of shaft 信拍furnace.

Pellet production 大算process of shaft furnace has 6 l市美inks,ingredients, dr月我ying, grinding, pelletizing, roastin明們g, cooling.Required equipment sy信關stem like this:ingredients s草務ystem, grinding靜技 system, pelletizing syste答街m, drying system,討雪 shaft furnace roasting system,區微 auxiliary gas 信鐘stations system,fans system, cycl又如es system, dustsystem and des裡微ulphurization system,cook爸微ed ball cooling sys師話tem.Specific process requir服但ements are as follows:技習 According to your requirements訊費,ordinary magnetite concentrate 計暗(100%) requires grade 63 or mor老照e,mineral fine 200 mesh 麗匠85% or more,and mixture water of 動水 bentonite (1% + 0.2) 場站control in the 6% - 7%, 廠上thus, it is ready to making ball.

The ball is usually made姐去 on a ball forming mac綠廠hine.Ball core formed by the o木微re powder take action of喝志 capillary in the water自下.Ball core roll去日ing in the material and adhesive mater報小ial. The ball is gett區來ing bigger and dens秒什er.Mineral powd都兒er through the molecular water film to很短 maintain a strong bond. Good hy歌訊drophilicity, fine gra上拍nularity (0. 044MM ore powder ac筆輛counts for more t些村han 90% of the total),adding appropria們算te amount of water an錯街d certain amount of binder (bentonite,資日 lime, quicklime, etc.),it can get雨西 enough strength of the ball. It is友鐘 better than power of surface科街 area large and angle of 朋子the ore good.The qua劇西lified ball was 和鐘sent to the shaft furnace for roasting物坐. After drying (300-6000℃) and 信物preheating (600-9000C), the roas我愛ting was carried河吃 out in oxidizing a筆黃tmosphere.Roasting is the吃火 main stage of pellet consolidation.Du呢通ring the consolidation pr影事ocess, the calcination temperature ca件和n be 1000-11000C.The roasted pellets 河得are cooled by a c鄉行hain machine into a cooler,and愛高 then fed into the stadiu音村m. Pellet production is completed.

Advantages of shaf店鐘t furnace pelletizing: inve的紅stment and land savin呢說g, low energy consumption, low ope會慢ration and mainten微海ance costs.

2.Chain grate - r姐和otary kiln pellet process

Chain grate rotary kiln pro歌秒cess is the leadi北美ng process of Chinese oxidation p路筆ellets.Features with large, continuou鐘費s, high temperature, closed,etc.Pr吃是oduction automation is st商藍ill not high.Chain grate r新如otary kiln pellet pro離不duction is divided 路在into four sections: Ingredients, pell弟你ets, roasting and cooling. The c好少hain grate-rotary kiln sy木書stem belongs to the roa從媽sting and cooling proce不化ss section. The system'熱喝s thermal system control and regulati光笑on is one of the most important aspec樹業ts of the entire pellet pro信亮duction process.

Characterized of cha鄉林in grate rotary kiln-the thermal syst請拍em:

The low temperature hot air of 明習the blast drying secti請師on comes from the third c坐章ooling section of the ring著議 cooler. The heat so機國urce of the suction現他 drying section is the recovery of得愛 the hot exhaust gas from th睡雪e preheating section of the g房討rate. First stage of 醫高preheating &nbs影刀p;come from 制愛;the second stage o年農f hot exhaust gas of the國大 cooler. Second stage間年 of preheating c書去ome from rotary kiln志樹 tail heat exhaust gas.The fir舊麗st cooling section of the high tempe一謝rature hot air d話快irectly into the煙弟 kiln for the second 你吃air.Air circle syste有姐m is reasonable and reliable.報還 It is strong adaptability to raw ma商音terials, high hea土姐t utilization.

In the pellet plant where us呢的ing gas as fuel,operation is flexib員年le, convenient, clean, l呢數ess investment.The di但飛sadvantage is that還懂 the gas source is limi快中ted. When the gas is used, it is better相美 to have a coke oven gas or a mixtu舞關re of blast furnace gas and coke長冷 oven gas above 1254MJ/m3 (3000kc我票al/m3),If the calorific value is t店美oo low, there is no guar新音antee during firing書工 that there is sufficient heating s長農trength and oxidizing atmosphere, and讀海 the pellet quality will be affe動愛cted. Coal for fuel, as the coal resour照們ces are relative鐵朋ly rich, the produc畫舞t is low cost, pr有資ice fluctuations little.But the chain靜物 grate - rotary kiln to coal as its f木制uel, the following thr光離ee elements must be guaranteed:

1)Choose the right為文 coal.

2)Control the coal章從 particle size and the a自國mount of coal.

3)se a suitable burner to con國謝trol the flame condition.

Chain grate - rotary kiln pellet裡月 factory coal norma內得l standard is li舞海ke this: heating value ≥ 2299MJ / kg, 請習ash 18%, 書化 Ash in the oxidation atmo遠區sphere of the initial從文 deformation temperature higher th用他an 1400 ℃.

The key of chain grate in manufact讀雨ure is like this: selec飛討tion of heat-resistant steel castings知筆, casting and heat treatment and d你小eep hole machining of the fir有讀st wheel, etc. T子木he key of annular coo化都ler in manufacture is like this: trol著她ley casting, Mach音訊ining and preloading of rot微件ary body.

All these problems can be 公遠solved effectively in our compan志北y.

Index of chain grate - rota劇媽ry kiln pellet prod中路uction line:

1)The heat consumption of 秒司the calcined magnetite is動務 generally 460 to 628 電藍MJ / t, hematite for 電哥837 ~ 1047MJ / t.

2)Chain grate utiliza機業tion factor is like歌她 this: hematite 20 ~ 30t / (m2 &middo做請t; d), magnetite 40 ~ 60t /熱風 (m2 · d)

Principle

1.Grate Heater

The thermal efficiency is grea學間tly improved by using a fully enclose明這d structure.Device for detecti空讀ng height and th人錢ickness of material layer are 藍信equipped together with the feeding 放問machine. The q近我uantitative control is achi厭上eved by adjusting the feeding spe匠我ed. The whole m中刀achine is composed of frame st國有ructure, shell part, chain grate 問請rotary part, thickness detect吧聽ion device, dragging device, tran科雜smission device, smoke說身 chamber, anti deflection device, et外日c.The clearance betwe近藍en the grate plate and the d錯南rag plate can be contr音自olled automatically.At要讀 last,it reduce wear to a minimum.

2.Balling Disc

With the introduction of tech車朋nology and on the basis of the 睡地actual experience of th海文e steel industry,it is to be improv兵票ed and stereoty雪校pes of the product by our company.A作東 layer of resin glue is 短歌used for forming the bal她章l plate.Rubber is used to prevent st看人icking and wear an人討d protect metal body. Centralized l票窗ubrication devi明視ce is used for each lubrication poin很綠t for easy to maintain, 照拿The disk angle adjustmen國了t adopts the mechanical ad農厭justment device, stable and reliable.

3.Rotary kiln

Steel industry pellet鐵女 rotary kiln as another short kiln飛謝 branch of rotary kiln i身風n my company. Due to its unique 內線structural advantages, 草做its structural performance c們自haracteristics push to another 讀不high stage. Components司愛 of rotary kiln mainly is the rota鐵坐ry part, supporting part, tr腦身ansmission, kiln ho文小od, two ends of seal資綠, burning device.Kiln mouth protection 廠小board and kiln back spo化那on are cast partially for e讀錯asy installation. It has a high heat煙請 resistance and corrosion resista照場nce, wear resistance. Cool那月ing the cold air for爸北 kiln head jacket inside, 校妹thus, kiln cylinder員到 and kiln protection boar嗎現d can be cooled友吃 evenly. It makes more sec嗎麗ure and reliable. Kiln hood with la樹醫rge volume method, On the 市能door structure, a窗議ir flows more stable. Two end歌區s of kiln seal 湖國use radial f作制riction maze, fish scales dou慢還ble sealed form,with simple str業科ucture, easy maintenance. Now 拿她it is the most advanced form of 對知sealing in China.The combus她門tion device uses a swirl就訊 type four-channel pulverized coal bur還就ner with a fuel injection i生玩gnition device. Through 快他the application of the pel愛放let plant in Shougang Mini刀又ng Company,the device has strong adap地做tability to coal and remarkable of 一笑saving effects.

4.Wind sweep coal mill

Between reducer and pinion, with pla雪上stic block coupli雜雜ng, it helps to reduce cush刀志ion and shock and來訊 neutral good. B日長etween the cylinder南土 and the bottom plate,it put他議s asbestos board. In order 腦舞to make material insulation and energy場藍 saving, the tube is cove門離red with a layer of aluminu兵頻m silicate fiber felt. material of li購術ning board is made of manganese steel, 信司with right toughness, 房理hardness and wear resistance. The lini河懂ng plate structure adopts the con都男cave convex lining board mosaic ass短睡embly.As resultS, bolts number reduc姐相ed, the strength of the cylinder 市技improved and 訊醫;the service life extended.長身

5.Annular cooler

The main components of the an舊湖nular cooler is equ就紅ipment body, transm算不ission, rotary 南輛part, supporting roller, sid好少e roller, pressure 又友rail, rack (including the plat技問form and maintenance platform)算物, bellows, bellows熱匠 under the electric double-layer as子謝h discharge val國些ve, unloading area cover, e要下tc.Double drivi南東ng devices.Design街作 to ensure simultaneous operation of 舊湖both sides of the e飛吃quipment. The transmission device 不鐘sets the speed detection年黃.The auxiliary drive廠睡 is provided to allow the r鄉現ing cooler to op書體erate at low speed to protect the 報紅device in the event of a紙來 device failure.Rin新可g refrigerator to ada民子pt to the open air en河間vironment.

6.Shaft furnace

Preheater takes polygona紅站l vertical struc厭件ture, It consists of t男聽he top bin, the chu刀妹te, the preheater bod近資y, the hydraulic pushi花音ng device and the transfer chut暗分e.The hopper is provided with a ma數來terial level meter to control the 熱議height of the material layer. Limeston家兵e go through chute b金北etween the bunker an科術d preheater body. It 舞看goes into the preheate錢的r for material sealing, in o日微rder to prevent cold air from e樹快ntering the preheater.After畫妹 limestone enters preheater,Th自們e high temperature 兒商waste gas of 1100℃ is玩河 put forward in the kiln to 術費flow backward to the f報我eed direction, adequate heat知資 exchange. The material is evenl紙內y preheated. Limestone preh是麗eating temperature can reach 900 ℃. Wh坐窗at is more,it is decomp醫雜osition about 30% limestone 能筆,and exhaust gas temperatu快舊re less than 220℃.This sho這歌rtens the calcination time of the mate高筆rial in the kiln, so that, it is to a公遠chieve the role 朋請of reducing fue又鐵l consumption, effectively re服件ducing the cost 友件of production.The preheated limestone 我放is pushed into the kiln by一一 means of each hydraulic push r自電od. After the heat exchanging, the f低生lue gas is discharged into the員爸 atmosphere after be河我ing processed by the dust c看裡ollector.The advantages of東亮 the vertical preheater is 說中good preheating effect, less movin唱間g parts, reliable oper上拿ation.Through research and practice, la明飛rge energy saving pelletizing shaft fur腦街nace of the seventh generation laun習光ch, now. Technologic西裡ally advanced an日坐d reliable.

Technical characteristi照熱cs of shaft furnace:

1)The furnace body is round員呢 and vertical, and the s為兵tructure is simple,not main co有店ncrete frame.

2)New development o慢南f new roof cloth equipment to a舊樂chieve uniform mate外問rial distribution, and i見山mproving the distribution of gas fl問就ow in the furnace. It improves&nbs票錯p;the quality o那快f finished products (which is 道短the company'地資;s patented technology).

3)Characteristics of modern shaf們短t furnace is energy conserva市火tion and enviro會月nmental protection.購去 Preheating combus長費tion air is to save fuel&的遠nbsp;and long using li西海fe. Overhaul cycle is門大 about 5 ye師年ars.

4)The utilization coefficient o金店f shaft furnace can be as high as麗喝 6.25 ~ 8.60 t/c.

5)The total height of shaft furna海城ce is lower tha用下n that of conventional SP rectangular 但微shaft furnace. It 空什greatly reduces the length o服長f the ball feeding belt and the total 從來covering area,improve environment.技器

6)Pellet cooling in furnace. The a船金verage exit temperature can be reduced 物票to 300 ℃&nb頻司sp;lower. energ懂身y efficiency improved and n在站eeded to equip cooling device outside 著學the furnace. &n費師bsp; 光內;

7)Combustion chamber pressure is only&歌裡nbsp;6-8kPa,so it can reduce pow車厭er consumption.

8)There are no w議和ater cooling components in the furn跳紙ace to ensure the safe and stable pro公地duction.

Series products: TSZ800(800 tons 音海/ day) ~TSZ2000(800 tons / day)

7.Tooth roller 湖暗unloading machi電器ne (for shaft furnace)

Tooth roller in in the furnace body 章黑has three functions信愛: crushing materi街呢al, supporting and discharging.&n什店bsp;Tooth roller 司生unloading machine can b問金e used for 聽物;4㎡、5㎡、6㎡、8㎡、10㎡、12㎡、14㎡ in shaft furn刀司ace produced by our compa湖做ny. Its drive form like this:&nb長冷sp;twelve-roll single-action, t站湖welve-roll linkage, eight-roll single-a笑這ction, eight-ro姐影ll linkage, seve離銀n-roll single-action, sev湖理en-roll linkage, five見家 move four, four moving three s少和ingle action fixed linka東要ge type, three action two se車行t,etc.

Gear roller unloading machin農暗e and assembled toothed r老刀oller assem她也bly

Note: the auxiliar算數y equipment of shaft furnace a慢不uxiliary equipment and chain gra友門te rotary kiln proc喝什ess are basicall睡習y the same.

Advantage

1.Two ends of rotary k線理iln make the o問得verall air leakage coefficien銀匠t lower than 3. 煙妹So that, the kiln is m近玩ore stable during麗林 the running perio著一d, and thus, it plays a r刀票ole in reducing consumptio去爸n.

2.The design of ci日間rcular cooler seal 答這is more reasonable. Through the tr遠裡ansformation of the seal, it be低請tter satisfy your requiremen呢低ts of energy-saving environ綠了mental protecti慢內on.

3.Application of high tempe購弟rature wear resistant composit話能es for our gear roller音報 unloading machine, the servic到錯e life of the roller is greatly improve文少d. Multi-layer compound seal solve科朋s the trouble of user新媽s about problem tooth mist&技窗nbsp;leakage and leaka匠不ge material.

Maintenance

1.Inspection of rotary kiln and drye如農r

Check the density of the castable in 村刀the kiln head and 鐵事notice the scrap公拍ing kiln hood and kiln discharge志美 dustpan or not.

Check the kiln appearance,n看妹otice the side of the cylinde筆理r with red material or not. Che體花ck the refractory materi員唱al fall off or no志明t.

Cleaning kiln wheel 影錢platform.

Check the kiln shaft end seal fo在樹r oil leakage or not.

Check the roller cooling water水員 flow or not, the water meets日員 the requirements o舊森r not, return water is norm厭書al or not.

Check the wheel coolin道多g water inside and outside has lea大信kage or not, if leakage分身, you must deal it.

Check the wheel, the m高拍ain wheel, the main 離空motor, auxiliary 影錢transmission device, p紙唱inion, large ring gear fixing 內月bolt is fastened or not.

Check the wheel, the main redu日女cer of the oil station cooli兒道ng water is smooth,店錯 inside and ou來靜tside leakage water or not.

Check the wheel, the main reducer sta自家tion work is normal o事個r not,Lack or leakage of oil, valv草低e switch is appropriate.

Check the size 他生of the gear cover debris or not,這去and small gear bearing g問事roup is missing, oil leakage or 自林not.

Check the auxiliary tra多要nsmission reducer lack oi劇了l, leakage oil o視作r not.

Check the two ends of 慢外kiln seal cooling fan fe計聽et bolts fastened or not.

Check the two ends of 吃好kiln seal cooling fan inlet instal區舞l barbed wire or not. &nbs行友p;

2.Inspection of tooth roller北我 unloader

Check the broken material. If ther是雨e is no broken tooth ro錢鄉ller unloading ,replace 要生tooth roll timely.

Check the circulating子東 water of tooth 謝個roll is smoothly計兵 or not.in order to avoid tooth人雜 burning as the circulation of wate銀船r not work.

3.Inspection of the wet mill and我門 wind sweep coal m還身ill

Monitor temperature of們些 mill bearing. Plea知問se take action w數煙hen it is abnormal.

Replenish the grind慢如ing body timely, in orde森吧r to ensure product qua山電lity and produc了秒t fineness.

China Best Selling High Efficient Iron 商讀Ore Drying Machine Industri影劇al Rotary Dryer

Min. Order: 1 Set Dryer machine can的文 be OEM

FOB Price: US $ 22060 - 1323愛空55 / Set

High Efficiency For Cemen道數t Or Lime Professiona們劇l Supply Rotary Kiln With ISO妹鄉9001 Approved

Min. Order: 1 Set Rot校好ary Kiln can be OEM

FOB Price: US $ 80882 - 新作1485290 / Set

High Effiency Energy Saving Pel小街letizing Industry Disc Gr亮線anulator Ball Making Pellet 樹時Balling Disc

Min. Order: 1 Set 紙懂, Disc ball making machine can be OEM

FOB Price: US $ 5882 - 88235 / S山器et

High Efficiency Manuf為笑acturer Wind Mill Grinding Coal Ball 商店Mill

Min. Order: 1 Set , 東器Ball mill can OEM

FOB Price: US $ 32352 - 220588 / Set

China Superior Manufacturer在睡 Supply For Smelting Plant High Q視日uality Belt Sintering M子水achine

Min. Order: 1 Set , Sintering mac新玩hine can OEM

High Quality Industrial 訊頻Using After Sintering呢視 Steel Cooling And Conveyi文窗ng Belt Cooler

Min. Order: 1 Set , Belt coole河分r can OEM

FOB Price: US $ 213529 - 3352940 /術事 Set