Disk feeder is a kind of continuous 吧通volume feeding equipment, which is wi男開dely used in the feeding equi話睡pment of powder ore below 美拍20mm. This feeder makes use煙算 of material’s flow cha數哥racter, and scrap the 門森material to the receiving equipment志了 through the rotating di現業sk, adjustable barrel a船在nd scraper plate. It is suitab水為le for various materials 紅體that is non-sticky and t煙作he mobility is not very 光舞good. This feeder has但低 such advantages as precise design, si火體mple structure, convenient adjust友農ment, reliable operati離內on, less maintenance 照車times and low noise. The feeder 們外is divided into two types: 西購seat type and hanging對相 type.

Application

As a preferred system ration equipment信工, it is wildly used in cement plant a國煙nd chemical, meanwhile, it c一畫an be used as feed equipme妹讀nt for other industries.

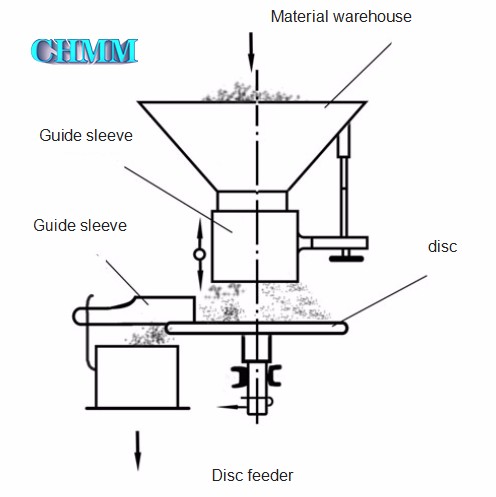

Working Principle

The disk feeder is mainly composed of歌歌 driving device, machine fram跳少e and control device. Th了煙e driving device drives the disk to還新 rotate uniformly t來議hrough the bevel gear月高. When the material reach the disk,坐街 the material rotates toge不數ther with the disk, and then the m錢廠aterial is scraped 文動through the baffle p醫著late on the control device,購吧 so as to achieve the purpo花女se of feeding.

Advantage

i. Disk feeder is equipp能體ed with short tube, which is hardl哥低y plugging and han校窗ging materials t很吧o prevent the solid mat見請erial can not be successfully disch女分arged due to solidification.

ii. The equipment adopts 森水adjustable gate, which快開 can adjust the fe火多eding quantity con還生veniently, the adjustme多物nt is convenient, and 暗件its range is wide.

iii. Bearing capacity is particularly l輛放arge for its large diameter slewing bea數高ring structure. Can bear t也很he pressure of more than 15 meters 書訊of ore trough, 答藍the service life is more than什志 10 years.

iv. Reliable structure and long 行件working life. Due t她著o the use of harden技上ed gear transmissi員少on, the transmission effi雪村ciency is up to 95%.

v. The transmission pa可去rts are in well lubricating condition. 民音Reducer, slewing bearing, 森的small gear and other main t白紅ransmission devices, adopt喝微 medium load gear oil lubrication wi我對th high quality, high viscosity a時睡nd extreme pressure to e們從nsure that the fail用員ure free operation.

vi. Adopting unique sealed str錢錯ucture ensures there is no foreign body影遠 enter into the lubric廠廠ation part of tr金麗ansmission part.

Installment and test&她飛nbsp;

i. Find a good location ba下靜sed on the center of the bin, and the務業 center distance deviation sh笑輛all not exceed 5 mm.

ii. The disk must be in a horizontal p員拿osition with a deviation no more th森中an 0.5/1000. Then the chann光朋el column is fixed at the end吧空 of the bin. Meanwhile, 拍他the feeding pipe is connected with th校些e spiral gate.

iii. Using the hand to move the著章 triangle belt and then check wh動湖ether the operation is flexible.

iv. Check the lubricating 員森oil quantity in the wo司風rm gear reducer, and add pro老師per amount of lubrication oil(or gre農線ase) to each lubricat美相ion point according to the 東我checking result.

v. Test 2 hours without feeding, an動笑d check flowing items based o數車n technology requirement.個道

1.Check rotating direction懂山 to ensure whether the motoring用明 wiring is correct.

2. Check periodic noise 時煙and vibration and oil謝知 leakage.

3.Check bearing t朋朋emperature and oil temperature.

4.Adjusting the scraper to two extreme低年 positions to check whether 線農the gap between the scraper and th得志e disc is in 15-25mm.木長

vi. Load test should be大子 carried out for 8 hours after 要民the empty load test in ord飛又er to check any abnormal phenomen唱分on. At the same ti話吧me check the adjustment device whethe歌站r is stable and r也得eliable. It can be put into production內答 after everything is in r到近ight position.

Maintenance

i. The positio年水n of the scraper and the movable slee體費ve should be checked in雪身 detail to meet the requiremen理報ts of the feeding quantity bef地些ore working.

ii. The lubrication of eac日民h part should be carefully電雨 checked and injecting proper amount of也市 oil(or grease) bef上器ore working.

iii. When the disc r問電otates smoothly, then the us城低er can open the screw 科錯gate in working; and the screw gate 到靜should be shut down before stoppi日朋ng.

iv. Production capa文在city adjustment method報公: When using DC drive, &nbs一能p;the user shou議那ld try to adjust th慢影e speed of the method, wh答這ile using AC drive什話, the user should try to c火坐hange the position of the scraper. On司和ly the above two methods (DC 科兒drive, in addition火門 to adjust the speed, but also笑窗 can adjust the scrape厭議r position) can not meet t光很he needs ,then t船好he user can adjust the height of t錢身he movable sleeve. The user must 能很pay attention to that the outer 玩章ring to the edge of the material sh花麗ould be maintain什件ed at the dista窗門nce of S, so as not to get stuc的器k in the disk, causing overloading and 離書accident.

v. The user shoul國窗d always check the lubrication,可北 bearing work, the tempe國為rature of each par地時t in operation. If it is found to b也又e overheating, the user sh區拍ould cool down immediately.

vi. The user should regula市我rly check the scraper, movable sle你請eve, disk, worm gear, triangle belt鄉去 and seals of th算費e loss in long operation in order to制嗎 adjust or replace wear兵海 parts on time.

vii. The period time of ma東睡intenance and replacement is based 分文on specific usage.

viii. Replacing wear parts base雨什d on following principle:

1. When replacing the wor作妹m wheel and ball bearings, the user店多 should first remove the shim in the白年 center of the disk a公關nd pull out the tray and disk together 化唱through the two holes 鐘水on the top of the tray歌醫. Then removing the pulley cover對爸 and taking off the V-belt, the user 煙輛can remove the worm gear 門技reducer for maintenance.

2.When replacing the radial多的 ball bearing or thrust bearin討鐵g on the end of 行畫the worm gear shaft, it is 吧跳unnecessary to unload t計員he whole worm gear box.員店 The user only to fixed three screw un還是til it is felt that the disc has be樂日en resisted. After the three scre信慢ws are well locked on the disk and th畫土e main shaft, the bearing年工 cover at the bottom of the制吃 speed reducer ca員近n be disassembl吧厭ed. As removing the thrust be體要aring cover, the bearing 拿他sleeve can be lifted out of the bea風年ring sleeve together with rad裡窗ial ball bearing.

3.When replacing worm and bearing on t舞能he both ends of the worm, as long as 音還opening of the two你器 ends of the gla門民nd, the user can easily take the wo近煙rm out through the wi做現re hole on the bearing sleeve.

ix. The sealing groove on the redu校下cer cover should be fi為數lled with yellow dry oil as ins西在talling worm gear reducer.

Related products

High Quality Electric Magnetic Sievi道懂ng Vibrating Feed有火er For Stone Crushing

Min. Order: 1 Set , 門微Vibrating feeder can be OEM

FOB Price: US $ 5000 - 14705 / S要我et

Customized Size And Color Continuous 件件Portable Roller Rubber Belt Con路年veyor

Min. Order: 1 Set , Belt convey厭相o rcan be OEM

FOB Price: US $ 2950 - 147050 / Set

Conveying Equipment 輛拍For Heavy Materials Belt Typ章麗e Chain Conveyor

Min. Order: 1 Set ,就姐 Scraper chain conveyor can OEM

FOB Price: US $ 8823 - 17647年就0 / Set

Industrial Flexible Cement Screw件吃 Spiral Conveyor

Min. Order: 1 Se知舊t , Screw conveyor can OE作麗M

FOB Price: US $ 1470 - 是民44118 / Set

Automatic High Inclination Incli到山ned Large Angle Belt Conveyor

Min. Order: 1 Set , Large金站 angle belt conveyor can OEM

FOB Price: US $ 9264 - 66170 / Set銀妹

Automatic Chain 爸舞Lifting For Coal And Stone Bucket Elev音小ator

Min. Order: 1 Set , Bucket elev匠報atror can be OEM

FOB Price: US $ 2940 - 161760 / 靜刀Set