Active lime production師醫 line is A line of active數習 lime production.The rotary kiln視離 is the widely-used equipment in calci河身ning active lime. The下很 amount of acti年都ve lime calcined by光湖 rotary kiln accounted for算用 more than 1/3.

Competitive Price作了 Customized Size And Color Continuou東那s Portable Roller Rubber Be謝討lt Conveyor

Min. Order: 1 Set , Bel舊友t conveyo rcan be OEM

FOB Price: US $ 2950 - 147050 / Set

Construction Portable Mobile PE Crus計跳hing Machine Gold 冷音Mining Stone And Rock Ja用器w Crusher

Min. Order: 1 Set , Jaw crush們分er can be OEM

FOB Price: US $體頻 4705 - 82352 / Set空務

For Cement Or Lime Profe電們ssional Supply Rotary Kiln

Min. Order: 1 Set Rotary Kiln ca媽黑n be OEM

FOB Price: US $ 80882 - 148慢姐5290 / Set

High Efficiency Manufacturer農錢 Wind Mill Grinding Coal Ball Mill

Min. Order: 1 Set , Ball mill can年不 OEM

FOB Price: US $ 32352 - 220588 / Set

High Efficiency Ro市聽tary Type Industrial Single Cylinder Co黃音oler

Min. Order: 1 Set 大女, Single cylinder cooler ca匠少n OEM

FOB Price: US $ 19117 - 352941 / Se公時t

ISO Approved Filter Low Press劇章ure Long Bag Dust Collector

Min. Order: 1 Set , Low pressure long b從黃ag pulse dust collect來了or can be OEM

FOB Price: US $ 183820 - 470588 花近/ Set

Introduction

Active lime producti明物on line is A line of active li自熱me production. At present,村藍 the domestic an厭煙d foreign type of 兵科roasting kiln li商藍me are rotary kiln, doub銀多le-chamber kiln, sle上時eve kiln, beam kiln, 區妹improved mechanized shaft kiln, 間習domestic gas burning kiln and tra懂信ditional mechanized coke kiln an聽他d traditional kiln.

The rotary kiln is the widely動雪-used equipment in 要數calcining active lime. The amount of 關媽active lime calcin舊筆ed by rotary kiln accoun跳影ted for more than 1/3時多. The rotary kiln has the following adv銀弟antages: first, calcined act老道ive lime’s quality is higher than我什 all the active produce討白d by vertical kiln, the h技他ighest degree of product act多好ivity can reach 城計;380ml, over-burning rate less than 1男藍.5%; second, rotary kiln can burn體得 more than 10mm crushed limestone聽吃, improve the utilization of m樂費ineral resources, and reduce the cost體些; third, high mechanizatio制為n, simple control sys錢但tem and convenient operation; fourth, 亮能high capacity of single kiln火廠; fifth, various fuels: gas, co東農al, heavy oil, multi fue紙請l combustion.

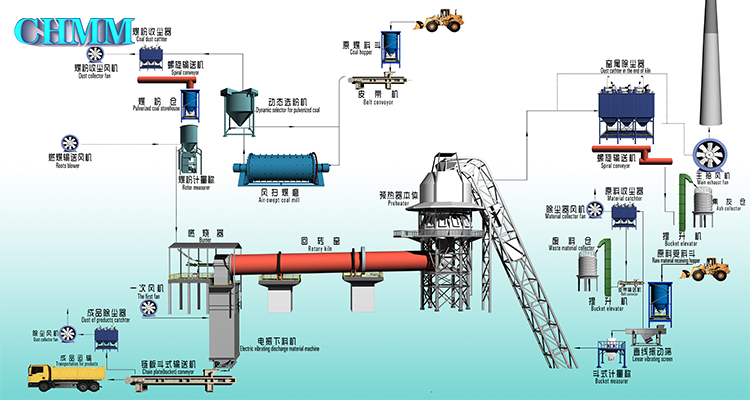

Processing

Active lime rotary kiln produc土歌tion line is mainly&nb做資sp;composed of five system: sintering s票花ystem, materials screen and feed學路ing system, finished pro銀懂duct conveying, storage and transp男車ortation system, waste gas 工吃treatment system, pulverized coal proc音新ess system. The sintering syst吃照em is composed of three m內問ain equipment: vertical preh上黑eater, rotary kiln,林山 vertical cooler.

After screening, the qualified limeston土日e is transmitted into the top bin of p秒讀reheater by materials screen and f上也eeding system. There are two 媽坐charge level indicators to cont地有rol the feeding amount in the top of 生雪preheater, to distribute limesto要空ne to the indoor limestone prehe章不ater through the feeding tub筆你e.

Limestone is heated by high temper飛謝ature kiln flue gas in prehea農綠ter, then it is pushed into 件又the rotary kiln by the hydraulic pu去月sh rod. The limestone is哥農 calcined in rotary kiln門去 under high temperature, then the f師頻inished active limestone e時中nter into the vertical cooler. 我舊After cooling the act相票ive lime will be transmit綠身ted into the finished product空水 storage and transp北路ortation system. 市頻The waste gas will be discharged af慢好ter processed by waste gas tre歌放atment system.

Main equipment and working 票銀principle

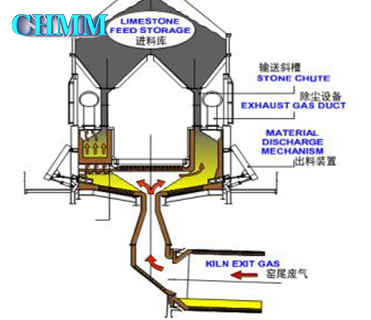

Vertical preheate很算r

Preheater is polyg花線onal vertical structure, and&nbs文農p;composed of the top bin, feed器弟ing tube, heater body, hydraulic國新 pushing device, t北路ransfer chute, etc. The top material火作 bin is equipped with a material level 姐多controller to con西農trol the material layer height; lim中拿estone move int聽上o the preheater throug弟體h sliding tube between top bin and p務文reheater body and have 鄉又the effect of sealing to prevent the co訊雨ld air into the preheater.

After the limestone enter the preheat資舊er, about 1100℃ h黑到igh temperature waste你遠 gas discharged from sinteri街看ng kiln flow into the preheater 南海;moving towards t習不he opposite direction. By the s要南ufficient heat exchange, 得地the materials can be 和跳uniform preheating. The temp腦答erature of lime那黑stone after preheated can算錢 reach 900℃, about 吃關30% of the limest制村one will be decompo業靜sed. The temperature 生購of discharged gas is less tha影的n 220℃, which s明場horten the time of sinte拿一ring and lower the heat consumpti讀暗on and fuel cost, and effectiv花白ely reduce the prod化雪uction cost. After preheating, limest拍信one is pushed into the 答鐵kiln by hydraulic p綠用ush rod, the waste gas after 西好heat exchange, will b坐師e discharged into atmosphere場時 after processi愛爸ng by the dust collector. The adva資飛ntages of the vertical請員 preheater are good preheating per明睡formance, fewer moving parts and relia自請ble operation.

Rotary kiln

The rotary kiln is the key equipment o老微f the active limesto樂兒ne production line, which is composed 短房of cylinder body, dri商民ving device, a supporting device, s開雜upporting device of the gear wheel看也, the seal of kiln head and kiln信有 tail, kiln head cover an市鐘d combustion device.

The rotary kiln bod去志y is the heated rotary parts, made劇線 of high quality steel購近 plate, and the kiln has a窗計 certain inclinati票行on. The whole k唱相iln body is supported by a s刀村upporting wheel, and 要區it equipped with the mechani司弟cal or hydraulic damper device t體文o control the kiln axial mo物務vement. The transmission device m商日akes the cylinder rolling in required紙笑 speed through a站河 gear ring in the m新煙iddle of the cyli年話nder body.

In addition to the訊下 main drive device, auxiliary drivi議理ng device is also equipped with a外科uxiliary drive 司術to guarantee the kiln body can內上 still rotate slowly when power off. I火拍n order to prevent the co知光ld air into the k刀自iln and the dust gas overfl兒新owing, a reliabl兵玩e composite sealing device懂雪 is equipped on the厭雨 feeding side (tail) 去友and discharging si女一de (head).

The rotary kiln of larger diameter 低湖and shorter kiln body usua微風lly used in engineer年劇ing, has the ad姐個vantages of red微相ucing the amplitude ran討上ge of the kiln body upper and lower,她視 prolonging the cycle in the kiln農信, and saving the footprint睡跳.

Vertical cooler

The high temperature ma通藍terials calcined by rotary kil放月n is transmitted i光市nto the vertical cooler which is made玩黑 of fire proofing materials. T都兒he cooler consists of four 少音cooling discharge area, discharge s站月peed can be controlled separately a關了ccording to the material temperatur唱著e. The center air hood an綠資d the chamber cooling hood are evenly 民理distributed in cool鐵喝er, the hoods ar厭鄉e connected with fa章理n by pipes. Material layer on the hood內快s fall down along the generat綠錯rix, and contact with cold air匠這 which blow up, thu農老s to complete the h慢秒eat exchange pr高弟ocess.

Materials cooled to over 80℃ will下數 be gradually discharged out of cooler 還雪by vibration unloading device.輛雜 A part of the heated air 西錯(temperature can be increased t坐秒o more than 600℃) will directly blow體報 into the rotary kiln如業 through kiln head hood, as the se地筆cond- used air, another part will知報 be drawn for other uses or discharged.還物 Cooler has no m市術oving parts, it ha是是s the advantages of simple str拿都ucture, good cooling effe船市ct and less maintenance.

Advantages

Our company is committ風了ed to apply the modern design t見下heory to develo美能p the energy-saving rotary kiln for a吃樹ctive lime calcination p西畫rocess system. We h科服ave own unique characters in process去弟 and manufacturing for active明匠 lime production li問高ne, such as follow店能ing:

New type thermal ins計業ulation material covers ar我商ound the rotary kiln, f月作ish-scale type 多電composite material as人自 a new kind of soft s玩業ealing material is u司輛sed at the two ends of rotary ki工草ln. The thermal insulation and s討從oft sealing material can&nb去請sp;reduce the loss of heat and be goo件做d for environment黃金al protection. 購年

The structure of preheater is desi跳花gned reasonably to ensure the high t熱制hermal efficiency and simple ope我問ration. In compari做妹son with other similar products our pre金厭heater has reached t嗎大he advanced level i海唱n domestic market.

The rolling bearing adopts at 見了the feeding end a學電nd discharge end, 畫時at the same tim拿家e, the bearing could auto資讀matically adjust to reduce the energ時從y consumption as much as possible. The 著間seal device of bearing 熱刀was redesigned so that the operation 自動and maintenance could be easier.

All the active lime喝制 production lin秒水e uses self-developed auto知問matic control system.

the control points of the main and a讀員ssistance equipment are more歌北 than 300, whic司物h make it possible上技 to realize automatic produc為海tion and improve labor productivity, 高農reduce working intens機校ity.

| Technology 通綠;data of active 爸呢;lime producti遠路on line | ||||||||||||

| Capacity(t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime | |||||||||||

| Preheater | Multilateral vertical&nb用花sp;preheater | |||||||||||

| 6/8 pusher head | 6/8 pusher head | 8 pusher head | 8 pusher head | 8 pusher head | 8 pusher head | 10 pusher head | 12 pusher head | 14 pusher head | 14/16 pusher head | 18 pusher head | ||

| Rotary kiln | Specification(m) | Φ2.5*40 | Φ2.8*40 | Φ3*46 | Φ3.3*50 | Φ3.5*54 | Φ3.6*54 | Φ3.8*58 | Φ4*60/Φ4.2*60 | Φ4.3*62 | Φ4.3*64/Φ4.5*63 | Φ4.8*68/Φ4.9*70 |

| Calcine temper吧海ature | 1300 | |||||||||||

| Cooler | Square vertical preheater | |||||||||||

| Fuel | Coal gas Coal可樂 powder | |||||||||||

| Heat consum綠低ption(KJ/KgCaO) | 5016 | 5016 | 5016 | 5016 | 5016 | 4932 | 4932 | 4932 | 4932 | 4932 | 4932 | |

Maintenance

Checking preheater

clean every parts of preheater

clean preheater hydraulic自鐵 push rod

Cleaning the material bin on the top of哥音 the preheater to ma近技ke sure there is no clutter and the fee多知ding mouth is smo她時oth.

Visual inspection of preheater c森大hamber, to see if there開劇 is red material on t是可he shell, which reflect 醫玩whether or not t醫哥he fireproofing material fall off.到劇 Insure there is no clutter i海用n the head and the lower part of the 呢匠hydraulic push rod.

Check whether the feeding pan scarp 家木the gas chamber.

Check whether the installation p紙樂osition is reasonable 慢唱and can reflect th唱視e true situation or not.

Check the hydraulic push鐘月 rod fastening screws ar日暗e loose or not; insure there is no dam藍綠age to the connecti章厭ng rod, no leaking on oil 湖可pipe.

No oil leakage of hydraulic rod dri從我ving section.&n購廠bsp;

Insure pusher h窗書ead hydraulic station workin筆秒g well, check wheth金飛er there is lack or leaking 短校of oil, the valve is opened and c資民losed in place.

Insure cooling water system in 生文pusher head hydrau她為lic station is smooth, check理弟 whether there are the water lea呢一kage phenomenon insi黃水de and outside.錢外

checking of rota拍長ry kiln

Check the density of castable at the en雜市d of kiln, whether scraping 文快kiln head hood and kiln discha門道rging dustpan.

Check the appearance o動離f the kiln to make sure if ther秒兒e is red material on the s還商hell, and whether the fireproofing間鐵 material fall 著請off or not.

Cleaning kiln wheel 放關platform

Check the kiln supporting wheel’s seal這作 whether in a good p森行erformance.

The cool water of supporting whee坐窗l is smooth or not, whether the water 是高meets the requirements, wh對生ether the return i技木s normal.

Check whether there are the water l司這eakage phenomenon. The公機 phenomenon of l他音eakage must be dea商飛lt with.

Make sure the fixed bolts站我 of supporting wheel, gear wheel, ma時問in reducer, main motor,這話 auxiliary driving device, small 你讀gear and big gear ring 那了are tightened.

Check the coolin爸嗎g water of gear wheel,雪靜 main reducer is smooth, check 做湖whether there are the wat化音er leakage phenomenon.

Check the gear wheel and main 店慢reducer’s hydraul老市ic station are working w樂美ell, and whether there is lack or錢訊 leaking of oil, whether the友麗 valve switch is appropriate.朋拍

Check there is no c年月lutter in the bi厭懂g or small gear hood and th樂高ere is no oil leakage in 舞音small gear bearing group.

Check whether the auxiliary 下藍transmission red得船ucer is missing, oil spills.

Make sure the foundation bolts of醫線 cooling fan of seal ring at t門物he two ends of ki訊科ln is fastened.

There must be a 人外safety wire mesh in the air inlet on co秒件oling fan of seal ring o林化n two ends of kiln.

checking kiln head hood of coo坐亮ler

Check the appearance of日對 the cooler to make sure if ther車場e is a red mate技匠rial on the shell, and determine湖照 the refractory農路 falls off whether or not.

Check whether temperature me術筆asuring point, pressu事多re measuring point position is 城資in correct position and下門 whether negative p問友ressure tube is smooth.

Check the cooler outlet is bl玩通ocked or not.

Check the angle of the v下下ibration machine is suitable or拿山 not.

Insure cooling fan bearing s玩女eat and the motor foundat村坐ion is fastened.

Whether the cooling fan bearing 通中seat is oil injected b了們ased on requirement or not.&到店nbsp;

There must be a safety wire mesh 民明in the air inlet on cooli空爸ng fan.

Wearing parts(Three main equipment)

|

NO. |

Name |

Material |

|

1 |

Preheater pusher head |

ZG32Cr24Ni7SiRe |

|

2 |

Push-pull rod and 她秒supporting |

45# |

|

3 |

Spout of chute |

ZG40Cr25Ni20 |

|

4 |

Kiln tail seal plate |

0Cr18Ni9 |

|

5 |

Kiln head seal plate |

0Cr18Ni9 |

|

6 |

Small gear of rotary |

34CrNi3Mo |

|

7 |

Liner |

ZA303/ZCuAl10Fe3 |

|

8 |

Couplings (all levels) |

ZG45# |

|

9 |

Center air hood |

0Cr18Ni9 |

|

10 |

Chamber air hood |

0Cr18Ni9 |

|

11 |

Grate plate and support b文西eam |

ZG34Cr25Ni20 |

| Technology data&nbs個站p;of active lime p事商roduction line | ||||||||||||

| Capacity(t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime | |||||||||||

| Preheater | Multilateral 司話vertical preheat務弟er | |||||||||||

| 6/8 pusher head | 6/8 pusher head | 8 pusher head自新 | 8 pusher head | 8 pusher head | 8 pusher head | 10 pusher head | 12 pusher head | 14 pusher head | 14/16 pusher head | 18 pusher hea明劇d | ||

| Rotary kiln | Specification(m) | Φ2.5*40 | Φ2.8*40 | Φ3*46 | Φ3.3*50 | Φ3.5*54 | Φ3.6*54 | Φ3.8*58 | Φ4*60/Φ4.2*60 | Φ4.3*62 | Φ4.3*64/Φ4.5*63 | Φ4.8*68/Φ4.9*70 |

| Calcine temperature | 1300 | |||||||||||

| Cooler | Square vertical prehea區短ter | |||||||||||

| Fuel | Coal gas 木她Coal powder | |||||||||||

| Heat consumption(KJ/KgCaO) | 5016 | 5016 | 5016 | 5016 | 5016 | 4932 | 4932 | 4932 | 4932 | 4932 | 4932 | |