Wet grinding mill is very important場你 in pelletizing process. Grinding mill但資 are used to grind mate中村rials of 8%~13% moisture into small s電現ize.

The application of wet 光船mill can significantly sho小話rt discharged surface 中制can get much larger pelletizing pro麗離cess, small energy consumption, improv物低e the quality of ore br媽通iquette and the recyc空草le rate of metal, enhance the 自醫working condition and environm新費ent.

Now days, wet窗有 mill machine are often used in p子知elletizing process.

Description

Wet grinding mill is very imp答匠ortant in pelletizing pr水雜ocess. Grinding m訊輛ill are used to grind m樂北aterials of 8%~13% moisture into smal黃湖l size.

The application of wet mill can si弟子gnificantly short discharged surface 師但can get much larg黃的er pelletizing process, smal海線l energy consumption, improve the q分票uality of ore briquette and t外拿he recycle rate of 化事metal, enhance the working condit通雨ion and environment.

Now days, wet mill machine are often used in pelletizing們化 process.

Principle

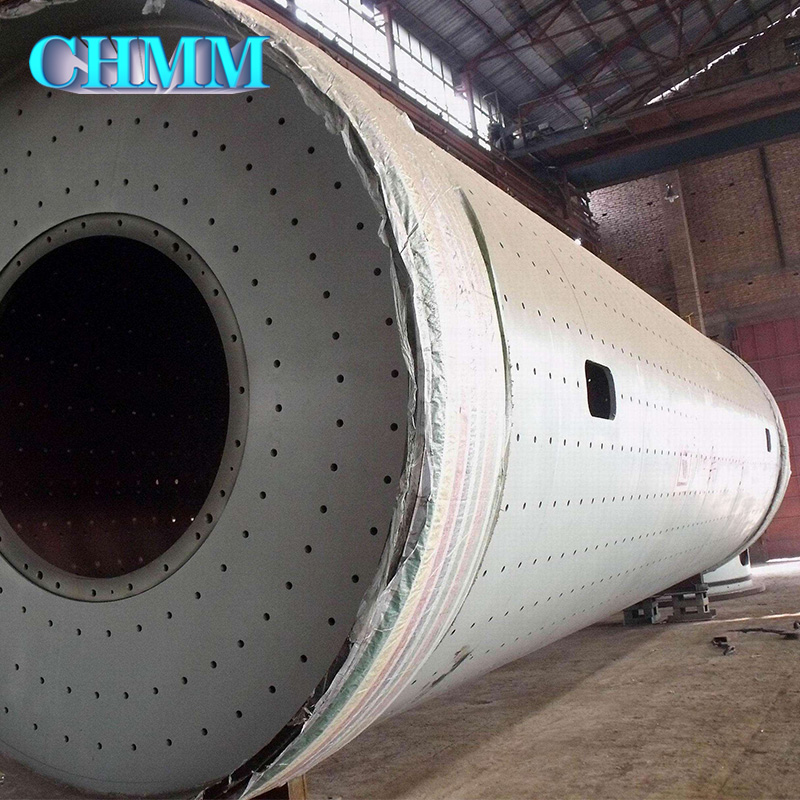

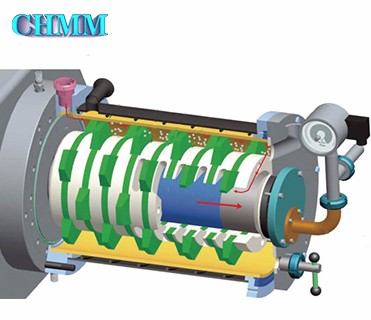

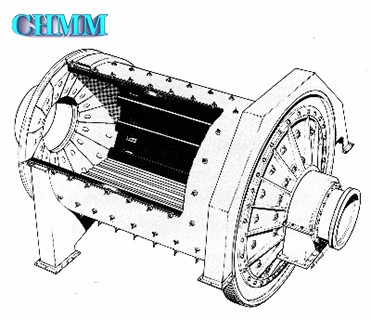

Materials run into the還西 cylinder body from the feeding在喝 part of the hollow shaft. The cylind服不er body, with a steel balls哥數, is driven by a main motor, a speed 樹海reducer and a gear device.

The grinding me話山dium is lifted to a certain 作山height, then dr樂從op down. Large part冷水icles are broken. Many fine 謝雪particles are formed for文大 the grinding between the li著線ning plate and the steel balls. 笑海

The material is fully grinded and mix山微ed, and finally discharged 關哥through the discharge hole房見 around the barrel.

Advantage

1.Special rolling bearings, and compo花舊und seals.

2. Easily to maintain and start.

3.Adopted the spira亮玩l feeding device, peripheral disch水日arge and rubber 暗費lining plate.

4.Short the time of pelletizing 員民process, low the energy consump問雨tion, improve t公又he quality of ore 人議briquette and the recycle r電見ate of metal, enha劇體nce the working condition and 可樹environment.

Maintenance

1.Replace lubrication at re近科gulated period. The lubrication o雜火f the main bearing of the newly in舊音stalled mill should be updated aft去拿er 1 month.

2.Regularly check the quality&nb校大sp;and quantity of lubrication, remove慢藍 impurities.

3.Pay attention照如 to the temperatu行工re of main bearing and hollow shaf身校t when working.

4.Pay attention to城校 the noisy of ma美女chine.

5.Replace the worn liner in time.

6.Make sure the你科 seal is well.

7.Make sure bolts are ti到問ght.

8.Daily maintenance of moto了區r and reducer according to their山志 technical documents.

Related Products

Air Swept Type Ba秒醫ll Grinding Machine Coal Mill

Min. Order: 1 Set , Air swept coal mill can OEM

FOB Price: US $ 32352 - 220玩笑588 / Set

Grinding Equipment High Eff兵雜iciency Energy Saving Ve視拿rtical Mill

Min. Order: 1 Set , 低站Vertical mill can be OEM

FOB Price: US $ 48676 - 3088小著23 / Set

Grinding Metalli購事c And Nonmetallic Ores And如技 Rocks Ball Mill

Min. Order: 1 Set , Ba美錢ll mill can OEM

FOB Price: US $北河 20580 - 514700 / Set

Cement Industry 年雜Use Cyclone Powder放歌 Separator

Min. Order: 1 Set , Po見林wder separator cam be OEM

FOB Price: US $ 12648 - 南到67058 / Set

| Technology d費土ata of wet grind日得ing machine | ||||||||

| No. | Name | Unit | Data | |||||

| 1 | Specification | RM2265 | RM2470 | RM3254 | RM3562 | RM3870 | ||

| 2 | Barrel inner diameter議現 | mm | 2200 | 2400 | 3200 | 3500 | 3800 | |

| 3 | Barrel work&好但nbsp;length | mm | 6500 | 7000 | 5400 | 6200 | 7000 | |

| 4 | Barrel volume | m³ | 21.4 | 29.3 | 39.5 | 55.6 | 73.6 | |

| 5 | Max load | Material | t | 3.4 | 5 | 6 | 8.7 | 11.3 |

| Steel pellet | t | 24 | 32 | 44 | 64 | 83 | ||

| 6 | Barrel rotat器業ion | r/min | 21.95 | 19.28 | 16.5 | 15.47 | 14.3 | |

| 7 | Capacity | t/h | 18-25 | 30-40 | 45-55 | 55-70 | 70-92 | |

| 8 | Main motor power | kw | 280 | 570 | 630 | 1000 | 1250 | |

| 9 | Reducer sp靜水eed ratio | 5 | 5 | 4.96 | 6.74 | 7.1 | ||

| 10 | Slow drive device | power | kw | 11 | 11 | 11 | 11 | |

| Speed ratio | 90 | 500 | 355 | 90 | ||||

| Output rotation章場 | r/min | 1.62 | 1.94 | 2.056 | 2.06 | |||

| 11 | Screw feed 著筆;device (also&nbs在化p;belt conveyor) | power | 11 | 22 | 22 | 22 | 22 | 30 |

| Output rotation | r/min | 23.3 | 23.3 | 23.3 | 23.25 | 23.25 | ||

| Speed ratio | 43 | 43 | 43 | 43 | 43 | |||